Power Supply with PCB WCPCBPSU

Power Supply with PCB for Disabled Toilet Control

12V 3A lockable battery backup box power supply including disabled toilet control PCB (WCPCB).

The WCPCBPSU has been designed for our Disabled Persons Toilet Locking Systems to use with automatic doors.

Battery not included

BEST PRICE

Prices that are hard to beat!

TRADE ENQUIRIES

Set up an online account or contact us for the current trade prices

GUARANTEED

Next-Day Delivery*

Reviews

You Might Also Like

-

Contactless Toilet Door Kit WCKIT-HAND

Contactless Toilet Door Kit Our touch free disabled persons toilet door opener kit, includes sensors, control...

£352.63Excluding Sales Tax | ShippingBUY NOW -

Disabled Persons RADAR Toilet System DGWCRADAR-KIT

Disabled Persons RADAR Toilet System ...

£704.99Excluding Sales Tax | ShippingBUY NOW -

Wireless Touch For Help Square Sensor SQTXHELP-KIT

Wireless Touch For Help Button Touch To Help Square 868MHz wireless sensor with scratch resistant, antimicrobi...

£114.95Excluding Sales Tax | ShippingBUY NOW -

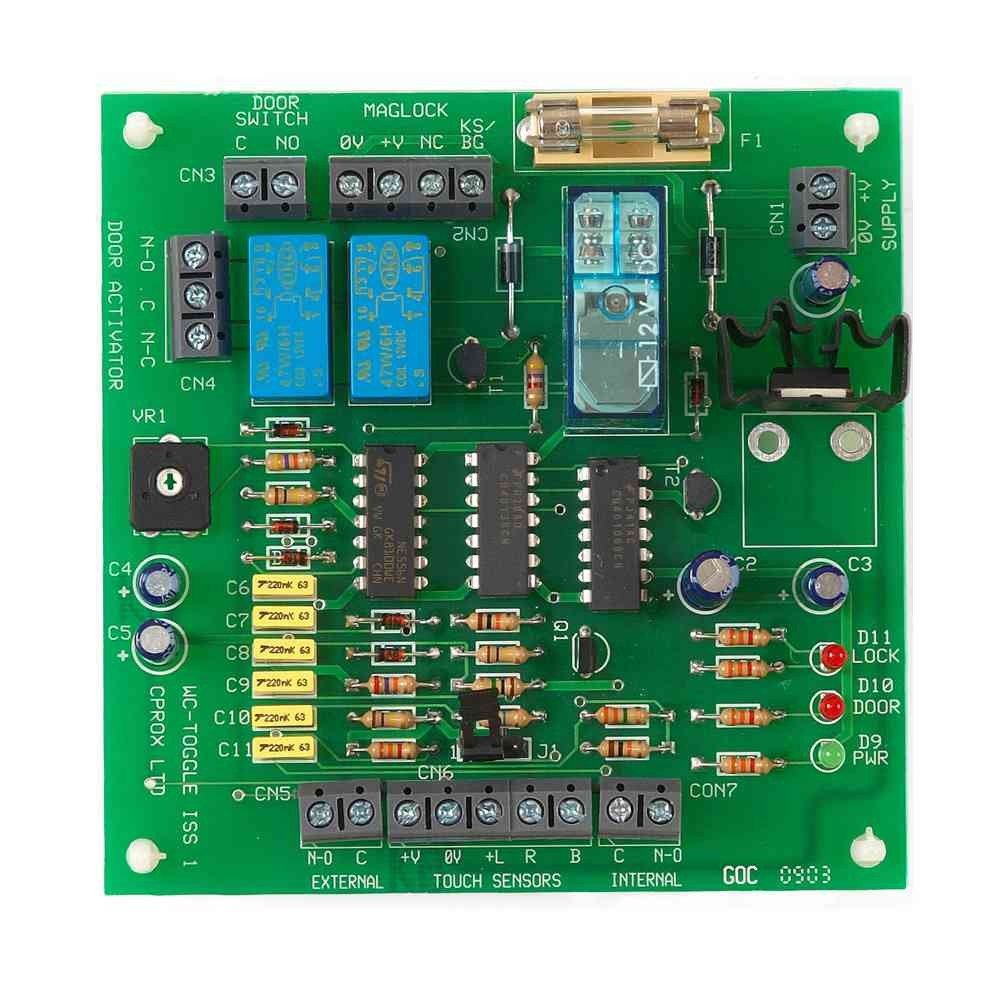

Disabled Toilet System Control Board WCPCB

Disabled Toilet Locking System Control Board PCB board for disabled toilet locking...

£99.48Excluding Sales Tax | ShippingBUY NOW -

MP3 Audio Message Announcer for WC Systems SGMP3-3

MP3 Audio Message Announcer for WC Systems SGMP3-3 MP3 Message Player - A great addition to...

£60.82Excluding Sales Tax | ShippingBUY NOW